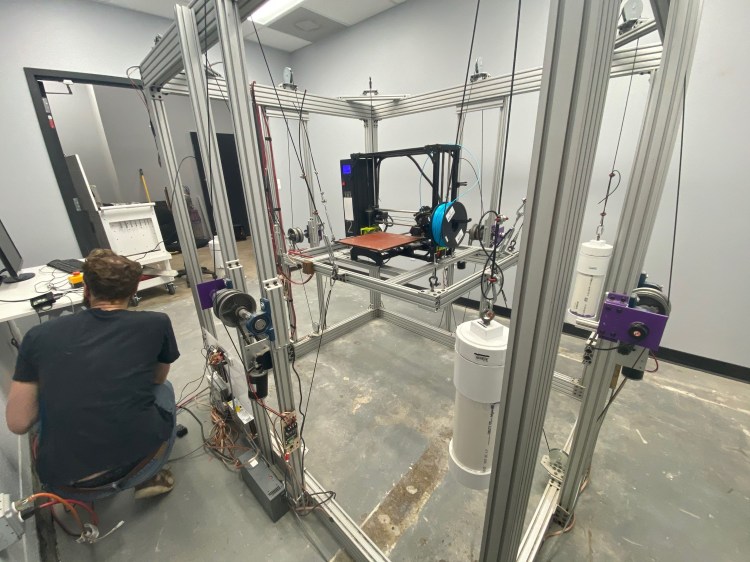

The goal of this project was to simulate a ship’s movement to test 3D printer performance, so the Navy could evaluate printers before putting them on their ships.

I worked in a team of four at Building Momentum to build this prototype in about three months for only a couple thousand dollars.

So far, we’ve tested it with a Lulzbot Taz 6, and it printed successfully! Check out this video to watch it in action.

Design

Our goal was to create a platform that could do roll, pitch, and heave either independently or simultaneously. We were inspired by cable robots for this design, and created a platform suspended by garage door cable and drums. We decided on four drums to make controls simpler and made most of the structure out of 80/20 with a number of 3D printed and laser cut parts for electronics integration.

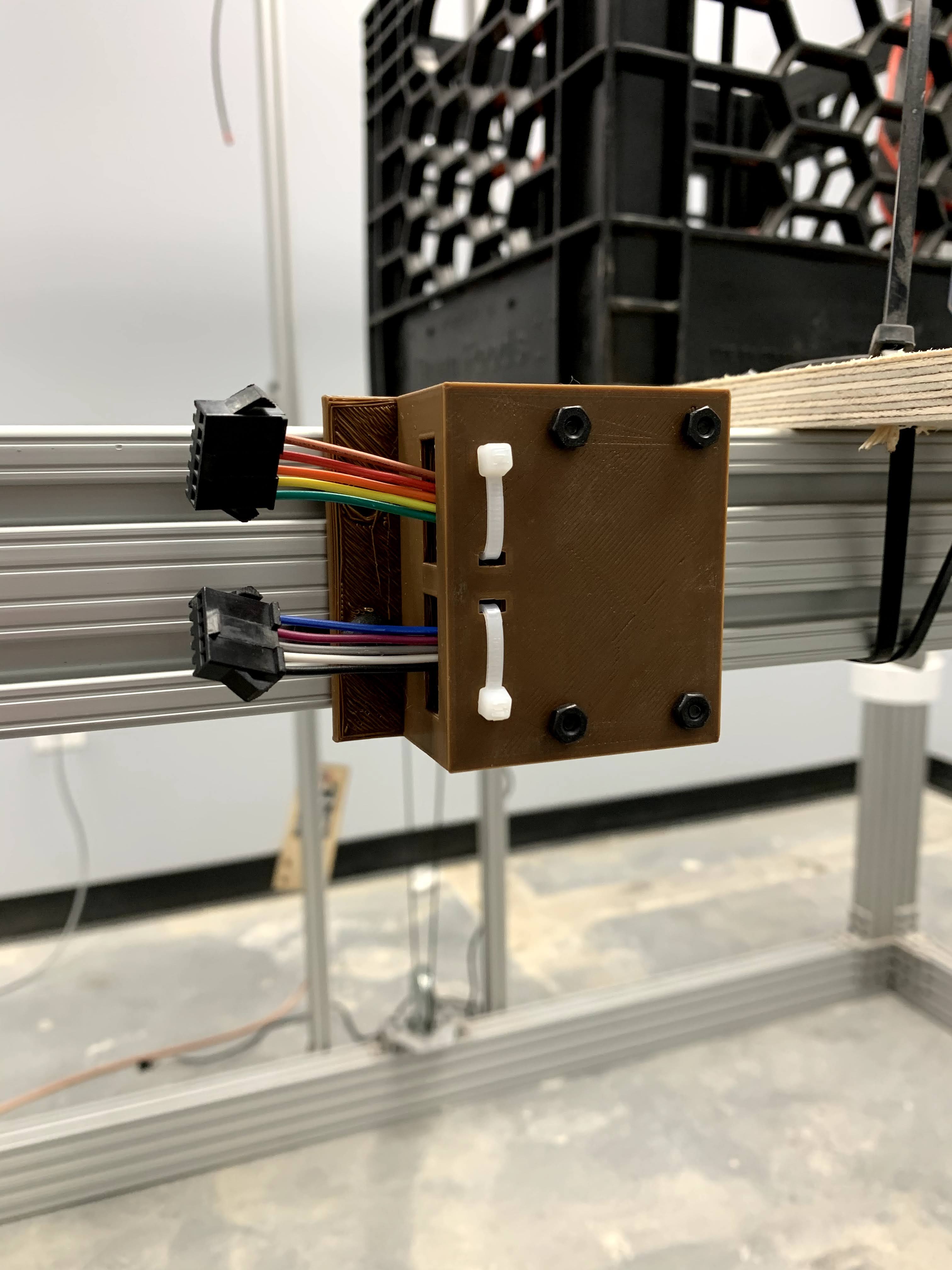

We also added multiple sensors including IMUs for giving motion data and a variety of air quality sensors to give us data to determine the need for a filtration system. I wrote code to read data from these sensors and display their data on an LCD screen, as well as designing and manufacturing PCBs to cleanly create the circuits consisting of multiple sensors and an Adafruit microcontroller. I also designed 3D printed enclosures for mounting these to the structure.

Controls

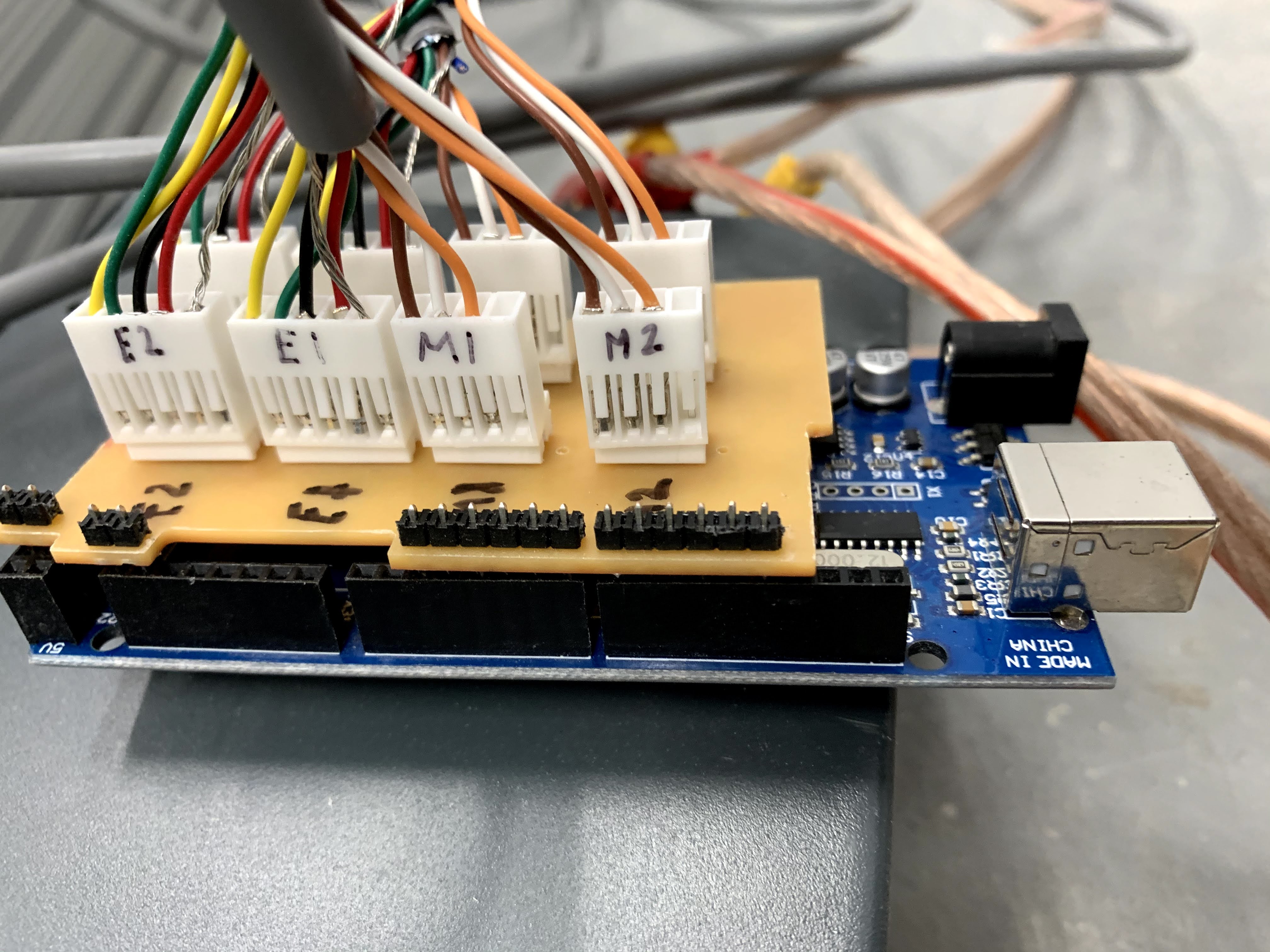

The system is controlled from an Arduino Mega connected over serial to a Raspberry Pi. A GUI is displayed on the Raspberry Pi, allowing the user to select the amplitude and frequency of the roll, pitch, and heave. I wrote the Arduino code that takes these user inputs, turns them into encoder targets, and uses a PID loop for each motor to control the motion.

I also designed a PCB that acts as an Arduino shield, connecting all the motors and encoders to their correct pins in a clean and simple package.